The Peak Pump Tubing Bailer is a fast and efficient way to clean out sand or other fill from a well. It is an efficient mechanical pump capable of removing large volumes of fill in a single trip. The Pump Tubing Bailer does not depend on hydrostatic differential pressure in order to operate and is therefore very effective in extremely low fluid wells.

Large volume of sand or fill can be cleaned out in one trip. The debris chamber is adjustable to accommodate any amount of sand or fill to be retrieved. The bailer assembly is designed with circulating drain ports eliminating the pulling of wet strings.

A specially designed hard faced drilling washover shoe on bottom of assembly allows rotation through compacted sand.

FEATURES:

- Heavy duty construction

- Operation simplicity

- Circulating drain valve eliminates wet strings

- Economical

- Cleanout can be accomplished in one run

- Effective in low fluid wells

OPERATION:

The Pump Bailer Assembly is made up on the tubing string with the required amount of chamber between the pump assembly and the valve assembly. The pump assembly must be spaced out so that it will be below the fluid level in the well for it to operate properly. Once on bottom, the pump is stroked up and down. As the sand is pumped up into the fill pipe, it is necessary to move the pump assembly down so that the bottom of the pump is always contacting the top of the fill. If necessary, the assembly may be rotated. Continue this operation until either bottom is reached or the fill pipe is full (will stop making hole).

When pulling, the tubing will drain automatically.

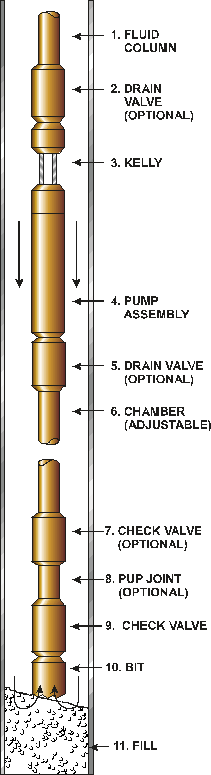

- FLUID LEVEL: The bailer is a hydrostatic tool that operates by having an overbalance of fluid in the well.

- DRAIN VALVE: The Drain Valve allows the tubing to drain while tripping out.

- KELLY: The Kelly provides the transmission of torque from the tubing string to the bit.

- PUMP ASSEMBLY: Applied compression to the pump assembly opens the main valve and the annular overbalance forces the fluid and sand in through the bottom trap valves and up into the tubing chamber. The sand and debris collects in the cavity pipe above the valves, while the fluid goes through the pump assembly and is discharged into the tubing above.

- DRAIN VALVE: The Drain Valve eliminate pressure build up in the adjustable chamber.

- CHAMBER: The Chamber is made up of tubing to accommodate the amount of estimated fill.

- CHECK VALVE: The Check Valve is of either flapper or ball design. The function of the valve is to maintain fill trapped in the adjustable chamber until surface is reached. The second Check Valve is run in case first Check Valve fails.

- PUP JOINT: Space out Check Valves.

- CHECK VALVE: As per item 7.

- BIT: Different bit types available dependent upon fill to be encountered.

- FILL: Completion or maintenance sand, surplus frac-sand or debris where well cannot be circulated.

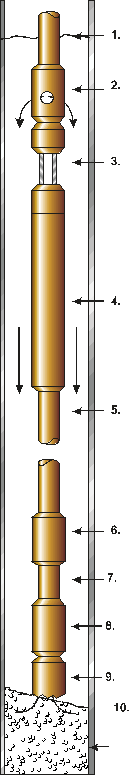

- FLUID LEVEL: The Fluid Level must be maintained above the circulating valve for the pump tubing bailer to function correctly.

- CIRCULATING VALVE: The valve has two functions with the first being of recycling of fluid during pumping operations. The second function is to drain tubing while tripping out.

- KELLY: The Kelly provides the transmission of torque from the tubing string to the bit.

- PUMP ASSEMBLY: Reciprocation of the pump assembly draws fluid and sand in through the bottom valves and up into the tubing chamber. The sand and debris collects in the cavity pipe above the valves, while the fluid goes through the pump assembly and is discharged into the annulus.

- CHAMBER: The Chamber is made up of tubing to accommodate the amount of estimated fill.

- CHECK VALVE: The Check Valve is of either flapper or ball design. The function of the valve is to maintain fill trapped in the adjustable chamber until surface is reached. The second Check Valve is run in case first Check Valve fails.

- PUP JOINT: Space out Check Valves.

- CHECK VALVE: As per item 6.

- BIT: Different bit types available dependent upon fill to be encountered.

- FILL: Completion or maintenance sand, surplus frac-sand or debris where well cannot be circulated.

Contact A Sales Representative